Time Management

How to use transaction RPTKOK00 and PT_BPC10

This document explains how to run RPTKOK00. This can be used to check for and fix database inconsistencies. An example of a database inconsistency error: an employee has accrued 2 days Compulsory Leave at the beginning of March, he books 2 days leave and then captures a number of unpaid leave days, Time evaluation is run which reduces his entitlement (because of the unpaids) from 2 days to 1.73 days for example. This causes a database inconsistency, the employee only has an entitlement of 1,73 days but has an absence record of 2 days. This can cause Payroll to not run successfully.

Program RPTKOK00 is able to pick up these issues and it will be useful to run this program before a live Payroll run.

Step 1

Go to transaction ZRPTKOK00

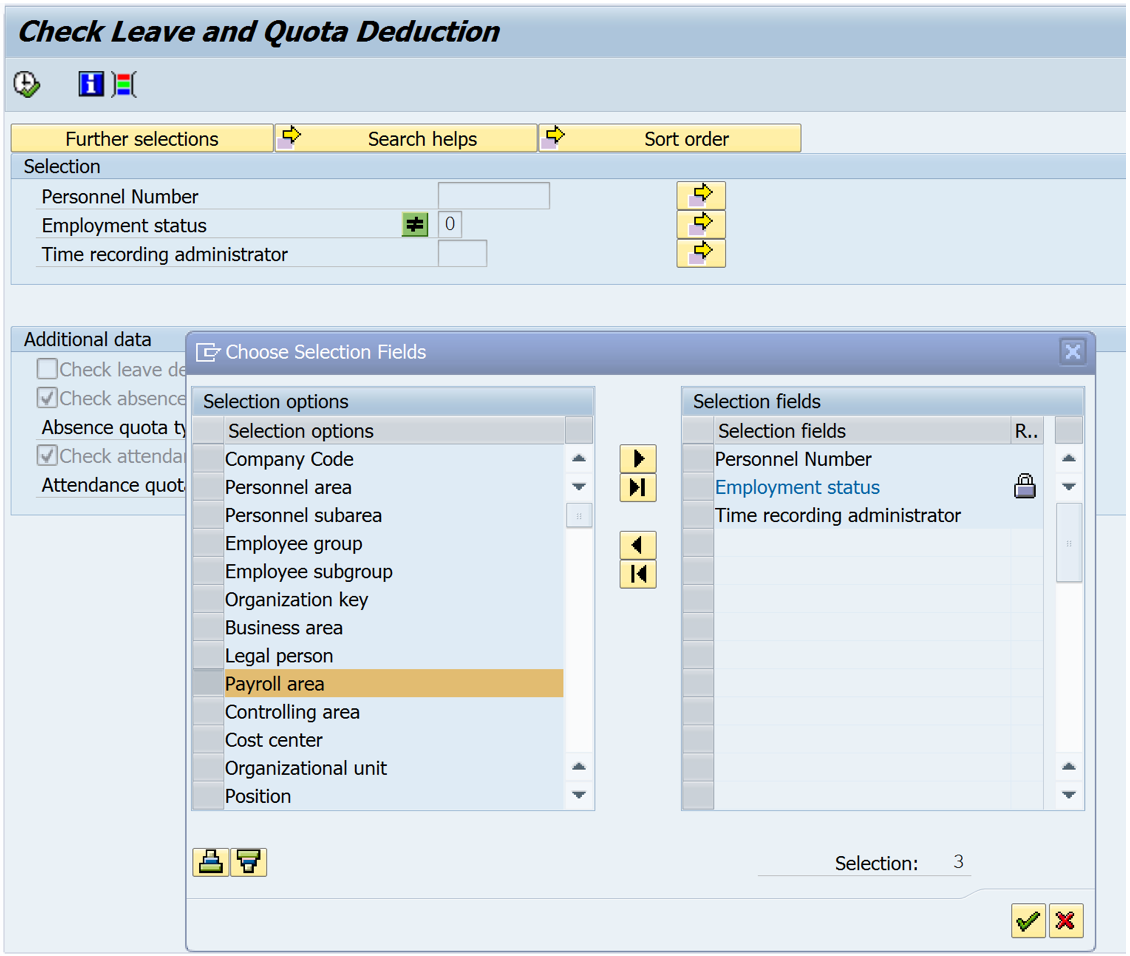

Click on “Further Selections”

Select Payroll Area and move it across.

Click on the green tick

Step 2

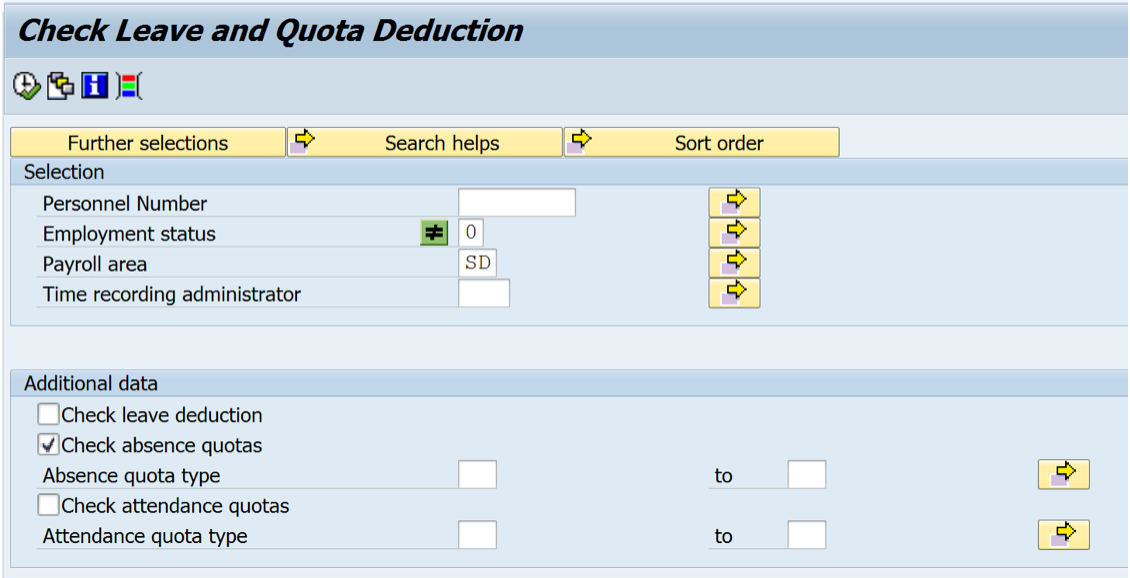

Enter your Payroll Area

Untick Check Attendance Quota (Not compulsory)

Click Execute

Step 3

1. This gives you a list of Employees with database inconsistency errors.

2. Select new deduction which will be able to automatically fix some of the inconsistencies. The others will need additional steps to fix (see the bottom of this document).

Step 4

Click Execute

Additional steps when program RPTKOK00 does not fix inconsistency.

In the example above where the employee had 2 days leave booked but an entitlement of 1.73 days, if the employee were to accrue another 2 days the following month then this program will be able to fix (recapture) the absence as there is sufficient entitlement to recapture the absence. If the entitlement is lower than the absence captured, the following steps can be followed.

A + 0.27 quota correction can be captured for March and - 0.27 can be captured for April (Time Evaluation must be run for quota corrections to take affect).

If your Organization permits it, Run Time evaluation to next accrual.

Reduce the leave captured to for example 1 day and book the other 1 day as unpaid leave.

For step 1 and 2 above, you will need to run the program after the step.

Additional Example

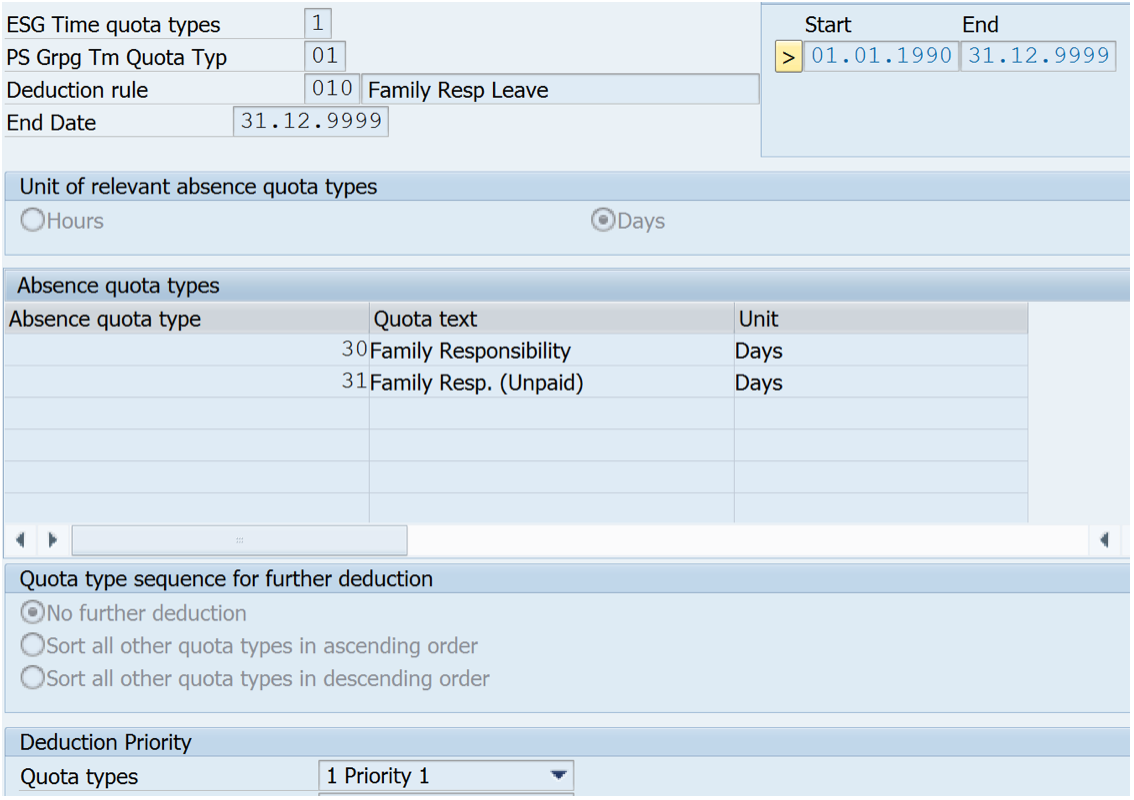

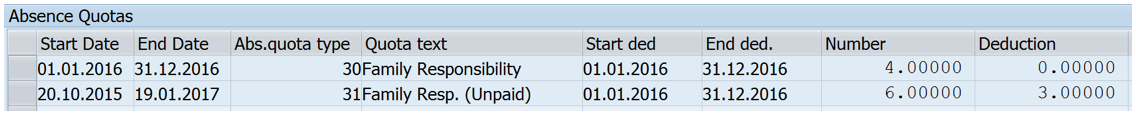

Table T556c is set to deduct first of Family Responsibility then of Family Resp. (Unpaid).

But you have a scenario as below where quota type 31 is deducted before 30 because at the time the 3 days were captured there was not enough balance in quota type 30 (for example 4 days of sick leave was incorrectly booked as Family at the time and has now been changed to the correct absence type thereby making the balance available now).

There are two ways to fix this:

1. Lock and unlock the absence and it will deduct from the correct quota once unlocked.

2. Run program RPTBPC10 (Transaction code PT_BPC10) as below.

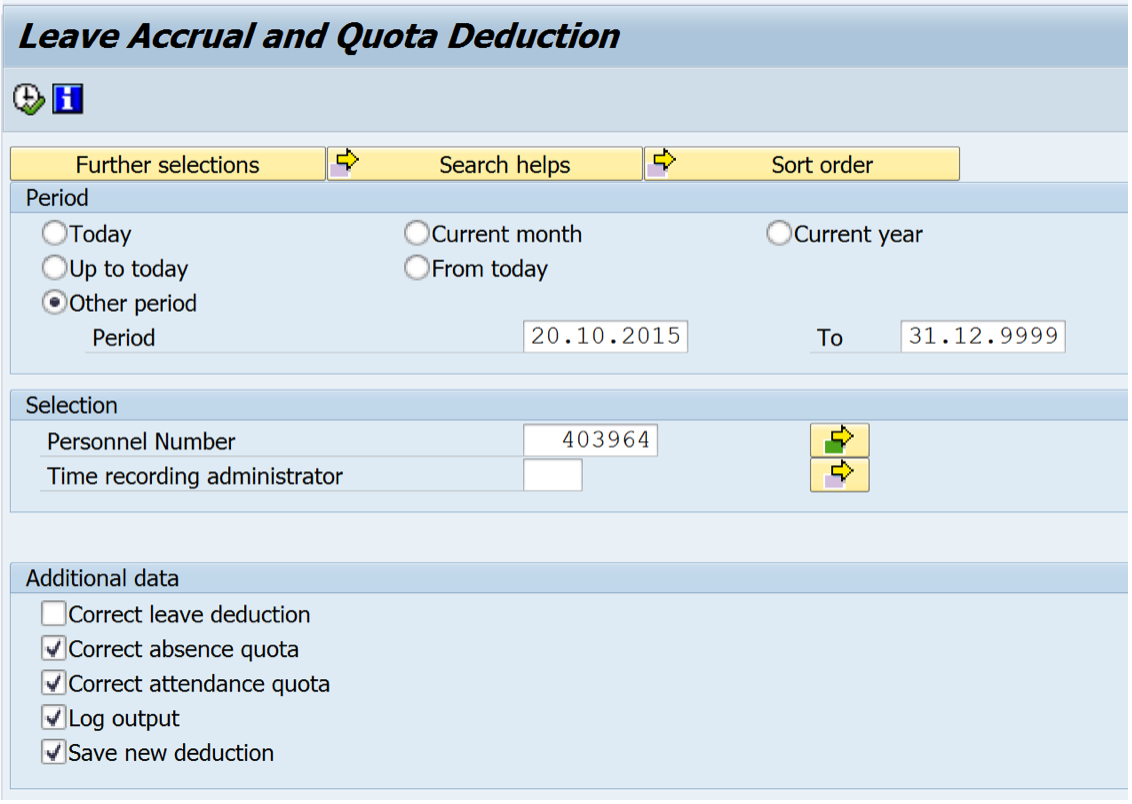

Go to transaction PT_BPC10

Enter the personnel no

Enter the period

Tick Correct absence quota, log output and Save New deduction (Correct attendance quota is not necessary in this scenario)

Click Execute

Corrections made are reflected

The absence has deducted of the correct quota now.

Fixing Time Evaluation errors when an employee moves from a grouping that does not have the new quota type

Summary of Guide

When an Employee moves from one grouping to another and the new grouping has a quota that the previous grouping did not have, depending on the dates, Time Evaluation can throw an error because in the employees previous grouping the quota being created does not exist. This can be fixed in config by adding the quota type in table V_T559l, under quotas and setting the quota to “no generation”), alternatively the following steps can be followed to fix this manually:

Run Time Evaluation with the log (PT60)

Double Click on the quota\s that are causing the error

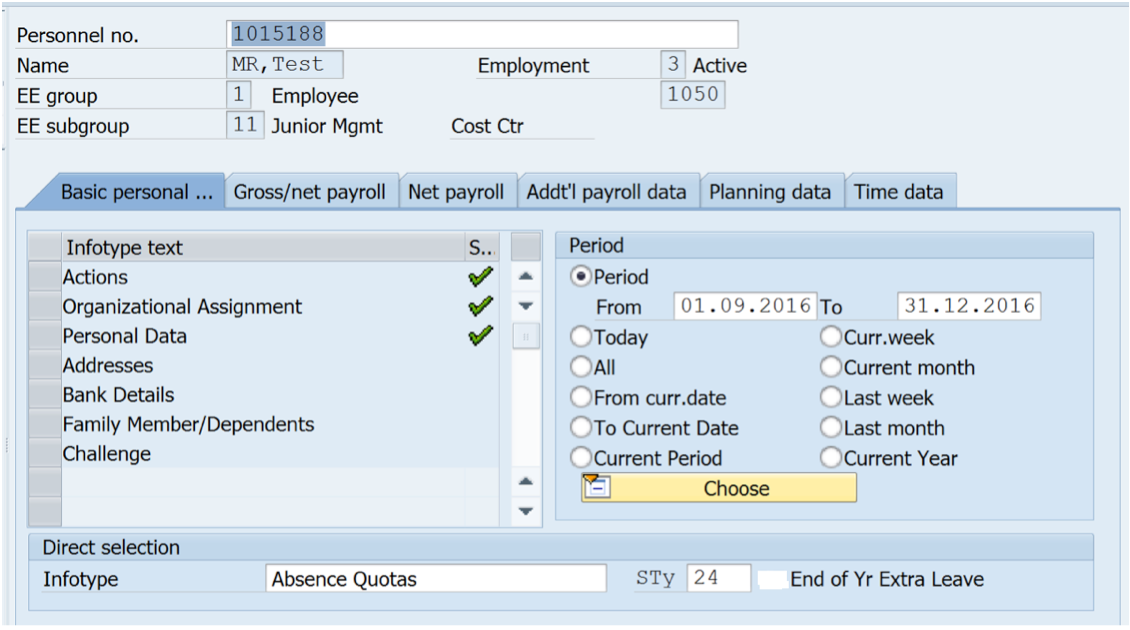

3. PT60 is trying to create a quota with a Validity Start Date of 01.01.2016, a period in which the employee was in a grouping that did not have Quota type 24

4. Manually Create the quota with a Validity Period that is the same as the transfer to new grouping date (in this case 01.09.2016)

5. Enter the deduction period as per what was in the Time Evaluation log (You might need to move the start date to the same date as move to new Employee group).

6. Run Time Evaluation