Learn how to do the following:

Automatic Usage Decision and follow up actions

Mass Result recording and Mass UD

Sampling procedure settings at plant level

1. Automatic UD and Follow Up Actions

Most of the time, Quality department would like to perform automatic usage decision and automatic stock movements based on recorded results. It is a key area which provides customer satisfaction, when they perform their daily work, whereas system provides assurance of validation and follow on activities.

To enable the same, SAP has provided many options, which provides a lot of value addition when used properly.

Automatic Usage Decision options and follow up actions

If the results recorded are not rejected, free of defects and all required characteristics have been confirmed, then SAP allows performing Auto UD.

Many times, there will be interfaces defined between LIMS / Quality lab systems / Level-II systems with SAP, to record the results. The quality management team would like to enter the results as and when operations are performed in the lab system and would like to fetch reports / certificates from SAP when the information is transferred. When the data is transferred and results are recorded, business will be more focused on spending time effectively, where issues are identified. To enable a smart management, the lots should be made Auto UD and auto stock posting, if all results are okay. In case of any issue, the lot should be open and user should action accordingly.

In SAP, the inspection type has “Automatic UD” option, followed by Plant level settings to define “wait time” if any. Once these are selected, QA17 allows creating a job that performs Auto UD, if above conditions are met.

In qcc0 settings for selected set, you can define the follow up actions and “Posting proposal UD”. The posting proposal “To unrestricted Use” can be set at this level for 100% acceptance level, to ensure that stock is moved to unrestricted use if all desired conditions are met. This will provide a lot of value addition to business, as Lab in-charge or QC Manager only need to focus on real issues, rather than going through each lot one-by-one.

Automatic UD at Client level

QCC0-> basic settings -> Maintain Settings at Client Level -> Further settings

Quality inspection Automatic UD can be activated at this setting, followed by event type linkage activation of event RESULTRECORDED under SWETYPV-> Business function BUS2045.

However, the client level settings are usually performed during initial phases of the project.

2. Mass Result Recording and Mass UD

There are cases when business requires performing RR and UD in mass. The regular options of QE01 / QA32 allow individual lot level activities. To avoid customizations on this area, it is possible to perform the below

QE71 - For Inspection Points

QE72 - For All Inspection Lots

QE73 - For Master Inspection Characteristic

For example, QE73 allows to enter results on tabular form, for a particular MIC Code.

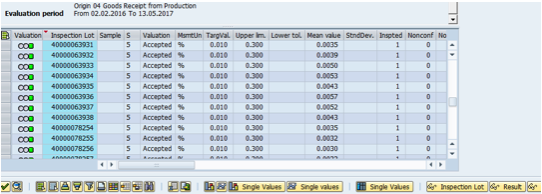

The result history option displays the history of results recorded for the MIC code between a desired timeframe, for reference:

Mass UD is possible using Jobs, planned through QA17 or manually using QA40. It is also possible to perform Collective Usage decision using QA16.

This is especially useful during order completion / month closing activities, to ensure there are no open lots. It is also helpful to use Transactions QVM1 and QVM3 to know the open lots.

3. Sampling Procedure Settings at Plant Level

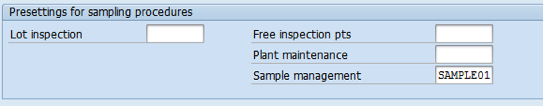

Pre-settings for sampling procedures are available at QCC0->Basic Settings -> Plant level settings-> Inspection lot creation.

To explain the purpose, consider the case where inspection at Physical samples needs to be carried out. It is mandatory to define sampling procedure and assign the same to all inspection characteristics when you define inspection plan for the same.

However, the sampling procedure may be relevant for few MICs in real business scenarios, whereas other MICs do not have such requirement. If the sampling procedure is set at plant level configuration as shown below, the sampling procedure is automatically copied, if there are characteristics to which no sampling procedure has been assigned in the task list or material specification.